Paper Powder Briquetting Solution

Large amounts of paper powder, scraps and trimmings are generated during paper manufacturing and recycling processes. These materials are bulky and low-density, making storage and transportation costly. Briquetting technology compresses loose paper powder into high-density blocks for efficient handling, recycling or fuel use.

Applicable Materials

- Paper mill paper powder and scraps

- Corrugated paper and cardboard powder

- Undersize materials from recycled paper production

- Paper waste from printing and packaging industries

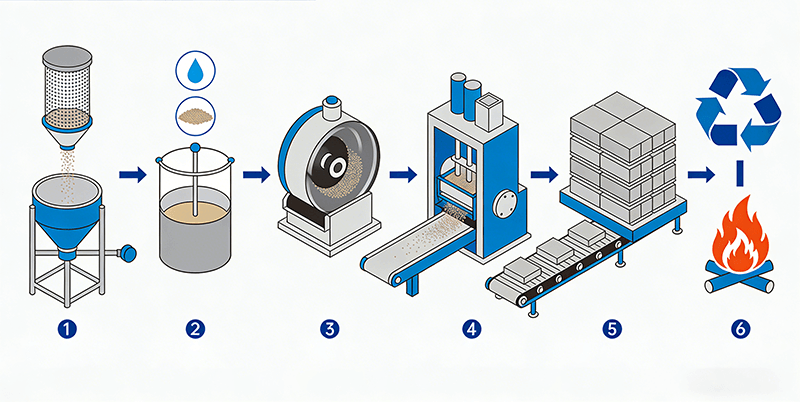

Process Flow

- Paper powder collection and screening

- Moistening or adding small amount of binder if necessary

- Uniform mixing

- High-pressure briquetting

- Finished product conveying and stacking

- Recycling or use as alternative fuel

Core Equipment

- Automatic feeding system

- Forced feeding briquetting machine

- High-pressure briquetting press

- Conveying and stacking system

Advantages

- Significantly increased bulk density

- Uniform briquette size for easy handling

- Low dust generation

- Low energy consumption

- No or minimal binder required

- Stable continuous operation with easy maintenance

Applications

Paper mills, packaging factories, printing companies, recycled paper processing centers, biomass fuel and boiler combustion projects.

We provide customized paper powder briquetting production lines based on material type, moisture content and capacity requirements. Contact us for detailed technical solutions and equipment selection.