Integrity & Professional & Quality

Energy-efficient & eco-friendly, turning industrial waste, mineral powders, and other powdered materials into high-value products.

Crusher

Vertical Crusher

Introduction:

The vertical crusher is mainly used for the fine crushing,sand-makingoperations of medium-hard materials. It adopts the "stone against stone multi-level impact" method to crush raw materials such as ores, cement clinker, and coal gangue into fine particles ranging from 0.5 to 5 mm.

Advantages:

- No mesh strip design, less prone to clogging.

- Flexibly control the particle size of the finished product.

- Can break down high-temperature and hard materials.

- When encountering an unbreakable object,it will automatically be discharged without damaging the equipment.

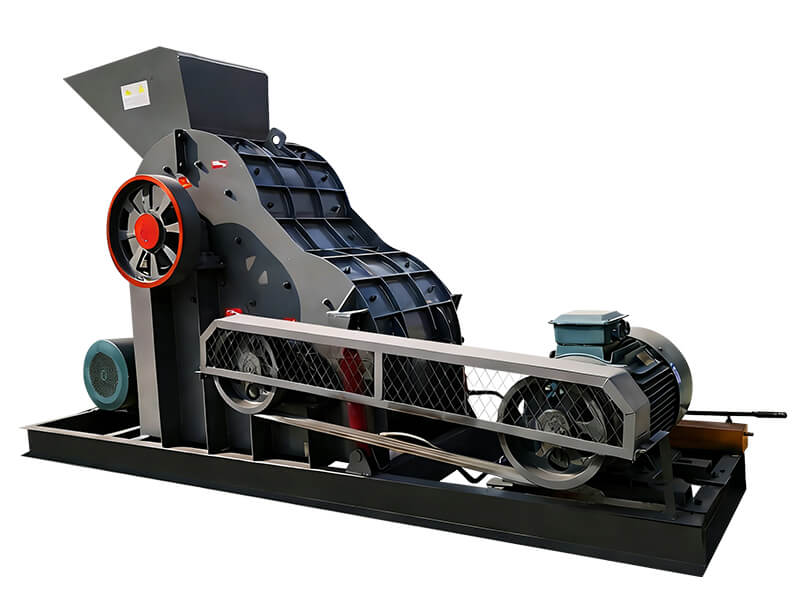

Hammer Shredder

Introduction:

It is an upgraded version of the traditional hammer crusher, It adopts the "upper and lower dual rotors + no bottom screen" design, specifically addressing the problem of blockage caused by high-humidity materials. It is a crushing equipment designed for high-humidity and medium-low hardness materials.

Advantages:

- Specialized for high-moisture materials.

- Specialized for fine crushing.

- Specialized for reducing wear-part costs.

- Specialized for boosting production efficiency.

Drying

Rotary Drum Dryer

Introduction:

The rotary drum dryer achieves the process of reducing the moisture content of the materials from a highlevel to below 12% through the combination of "hot air flow and material turover".It is widely used inindustries such as mining,construction materials,and environmental protection.

Advantages:

- Strong capacity and adaptability.

- Reliable drying uniformity.

- High production flexibility.

- High long-tem operational cosl-effectiveness.

Mixer

Wheel Mixer

Introduction:

The Wheel Mixer integrates the functions of "crushing + mixing", specifically designed for achieving uniform mixing and plasticization of high-humidity/high-viscosity materials (such as brick molds refractory materials)

Advantages:

- Superior mixing pertormance.

- High-quality cnd product.

- User-friendly operation.

- Enhanced sealing capability.

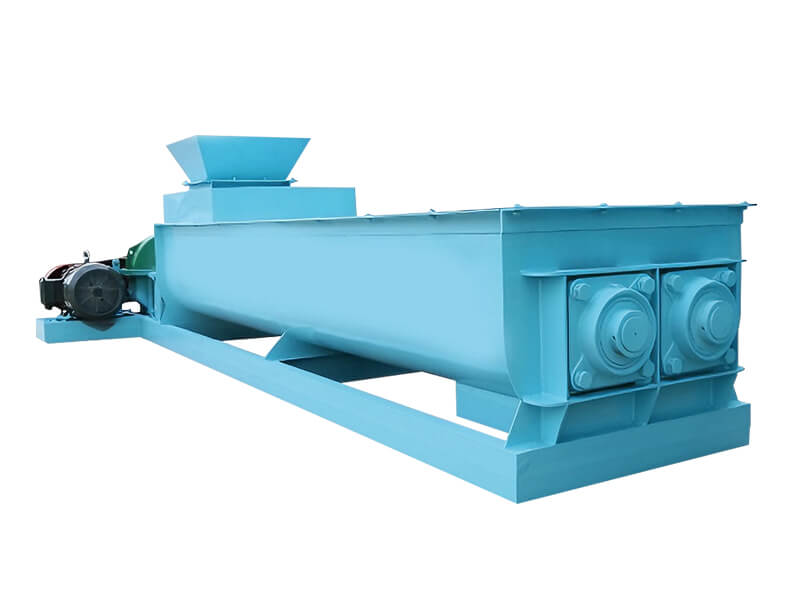

Twin-shaft Mixer

Introduction:

The Twin-shaft Mixer is a device in the industrial fieldthat integrates the functions of mixing, humidificationand transportation. It can process dry powder materialsto a dust-free state and is widely used in industriessuch as power plants and mines for the environmentalprotection treatment of dust/materials.

Advantages:

- Strong durability.

- Easy operation.

- Wide adaptability.

- High efficiency

- environmental protection.

Briquetting

Mechanical Pressure

Introduction:

Mechanical briquette machine is an industrial device that compresses loose powdery/granular materialsinto high-density blocks (or spheres) via mechanical pressure, Its core function is to convert hard-to-handle bulk materials into formed products that are easy to transport, store and use.

Advantages:

- Mechanical transmission can operate continuously for a long time and has high production capacity.

- Lower energy

- costs than equtvalent hydraulic presses.

- The mechanical structure is mature,with few potential failure points and low maintenanoe costs.

- Robust structure and long service life.

Hydraulic Pressure

Introduction:

Hydraulic briquette machine is a molding device that uses hydraulic transmission technology to compressvarious powdered and granular materials into high-density pellets, Compared with mechanical briquettemachine, it boasts superior pressure controllability amd forming density.

Advantages:

- Strong pressure controllability.

- The formed briquettes have 10%o-20% higher density than those produced by mechanical briquettingmachincs.

- Extending the service life of molds and pressure heads by over 30%o compared with mechanical models.

- One machine for producing briquettes of multiple shapes and sizes.

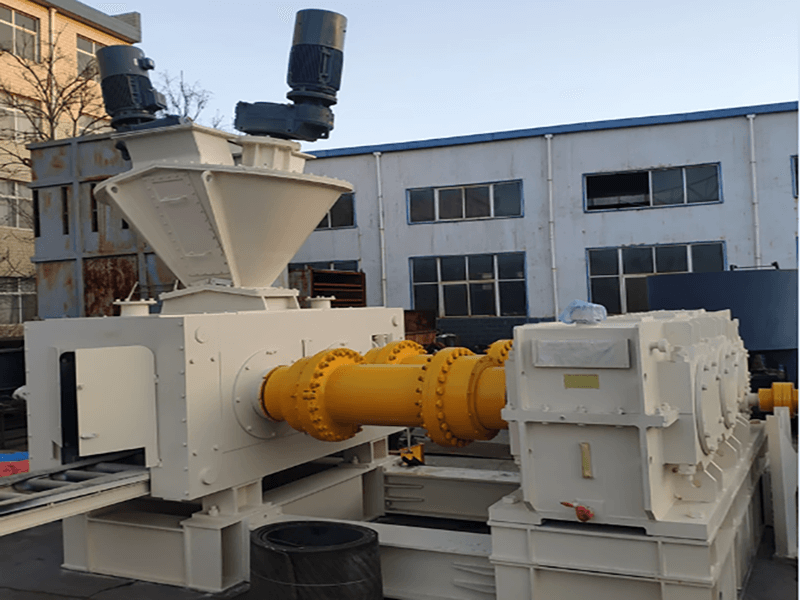

High Pressure

Introduction:

The High-pressure Briquetting Machine adds a spiral pressure device to the Hydraulic BriquettingMachine, compressing various loose, powdery, or granular materials with very little or even zero moistureinto dense,regularly shaped briquettes.

Advantages:

- The briquettes have hnigh hardiness and low water absorption,not easy to break, during storage andtransportation.

- Adopt PL,C control, reduce manual operation, improve production efficieney.

- Low energy consumption.

- Replaceable molds can meet the forming needs of different materials and different shape briquettes.

Premier Pressure

Introduction:

The Premier Pressure Briquetting Machine is an advanced industrial device that utilizes hydraulic transmission technology combined with a unique high-pressure forming mechanism to compress various loose, powdery, or granular materials into high-density briquettes. It is designed to meet the demand for high-quality briquettes in industries such as metallurgy, mining, and environmental protection.

Advantages:

- High-pressure forming mechanism ensures superior briquette quality.

- Advanced hydraulic transmission technology provides precise control.

- Suitable for a wide range of materials including coal, biomass, and industrial waste.

- Excellent durability and low maintenance requirements.

Auxiliary

Flip Dryer

Introduction:

Flip dryer is a continuous production equipment heated by electricity, steam, or hot air. It uses steel chain plates as a conveyor belt to continuously dry materials.

Advantages:

- Super strong Load-bearing capacity and Impact resistance, suitable for heavy and harsh materials.

- Fully closed leak-proof design, zero material loss.

- Corrosion and High temperature resistance, long service life.

- Directional hot air contact, precisely controllable drying rhythm.

- Low maintenance cost, adaptable to complex working conditions.

Mesh Belt Dryer

Introduction:

Mesh Belt Dryer is a continuous multi-layer belt dryer that uses a circulating metal mesh belt as the material conveying carrier. It achieves moisture evaporation through full contact between hot air and the material, and is widely used in large-scale material drying operations in industries such as industry, agriculture, and food.

Advantages:

- Cross-flow hot air drying, industry-leading uniformity.

- Multi-layer stacked design, ultimate space utilization.

- Outstanding energy-saving effect, lower operating costs.

- Wide adaptability, strong material and heat source compatibility.

- Convenient cleaning and Maintenance, meeting food-grade standards.

Contact Us

E.P MachineryZhengzhou City, Henan Province, China

WA: +86 136 3371 3237 (Chris)

sale@ep-machine.com