Mineral & Metallurgical Briquetting Solution

During mining and metallurgical production, large quantities of mineral fines, metal powders and undersize materials are generated. These fine materials are dusty and difficult to transport or use directly. Briquetting technology compresses powders into high-strength briquettes, improving smelting efficiency and enabling resource recycling.

Applicable Materials

- Iron ore fines and concentrate

- Manganese, chromium and nickel ore fines

- Steel plant dust and sintering return fines

- Reduced iron powder and mill scale

- Metallurgical slag fines and furnace dust

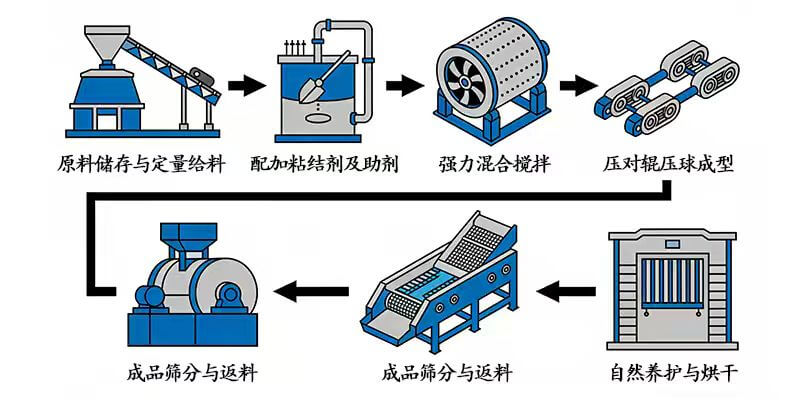

Process Flow

Core Equipment

- Quantitative feeder

- Twin-shaft intensive mixer

- High-pressure roller briquetting machine

- Screening and conveying system

Advantages

- High briquette strength and durability

- Uniform shape and size

- Improved furnace permeability and smelting efficiency

- Reduced dust emissions

- Low binder consumption

- Suitable for various mineral and metallurgical powders

Applications

Steel plants, mineral processing plants, non-ferrous smelters, pellet plants, sintering plants and metallurgical waste recycling projects.

We provide customized mineral and metallurgical briquetting equipment and complete solutions. Contact us for detailed specifications and project references.