Quicklime Briquette Machine:Efficient Industrial Molding

Overview

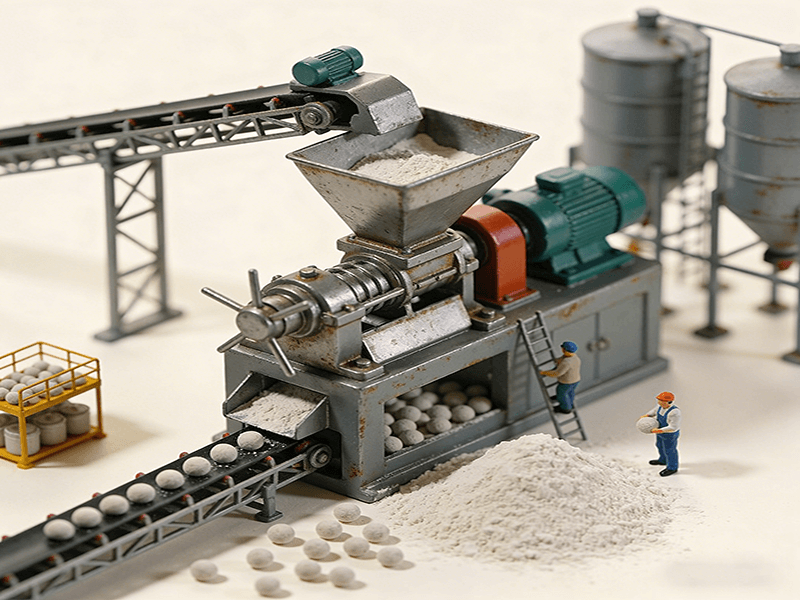

A quicklime briquette machine (also known as a dry powder briquette machine or lime powder briquette machine) is a specialized device that compresses powdered quicklime into spherical pellets under high pressure.

It can press loose quicklime powder, limestone powder, and other materials into high-density balls, effectively solving dust pollution and transport loss issues, while improving material efficiency in metallurgy, chemical, and construction industries.

Why Use a Quicklime Briquette Machine?

- Environmental Protection & Energy Saving: Directly press dry powder without adhesives or water, avoiding safety hazards caused by exothermic reaction of quicklime with water.

- Improved Utilization: Pellet density can reach 1.9–2.2 g/cm³, reducing raw material waste during high-temperature smelting.

- Cost Reduction: Pressed pellets are easy to transport and store, lowering logistics and warehousing costs.

Core Equipment Types & Features

Common quicklime briquetting machines include:

- High-Pressure Briquette Press

- Features: Pressure up to 50–150 MPa, capable of pressing hard materials such as quicklime and metal ore powder into high-strength pellets.

- Applications: Flux pellets in steel plants, coke powder molding in coking plants.

- Dry Powder Briquette Press

- Features: No need to add water or adhesives; directly press dry powder with moisture content < 1%.

- Advantages: Simple process, low energy consumption; suitable for chemical and building materials industries.

- Lime Powder Briquette Press

- Features: Designed for 80–200 mesh fine powder; smooth surface, resistant to breakage.

- Metallurgical Briquette Press

- Features: High temperature and wear resistance; can process steel slag, dust removal ash, enabling resource recycling.

Choose the Right Manufacturer – Save Time & Money

E.P Machinery – China’s Leading Quicklime Briquette Equipment Brand

With 15 years of industry experience, E.P Machinery provides efficient and energy-saving briquetting machines to over 300 enterprises in steelmaking, chemical environmental protection, and building materials industries.

Advantages:

- Technical Guarantee: Independently developed high-pressure dry powder briquetting technology; ball density > 2.2 g/cm³, suitable for quicklime, calcium carbide slag, metallurgical dust, etc.

- Case Endorsement: Served industry leaders such as Baosteel and Conch Cement; equipment operates continuously for over 8,000 hours.

- Customized Service: From single lime powder briquetting machines to metallurgical production lines; hydraulic systems and alloy rollers configurable.

- Worry-Free After-Sales: 24-hour response for debugging/repair; lifetime spare parts support.

Equipment Maintenance

- Regular Lubrication: Check lubricating oil in roller bearings and gearboxes every shift.

- Clean Residual Material: Remove powder adhering to rollers after shutdown to prevent hardening.

- Building Material Production: Use briquetted lime powder for cement calcination to improve combustion efficiency.

- Check Wear: Replace roller dies when wear exceeds 3mm.

The quicklime briquette machine has become key equipment in metallurgy and chemical industries due to high efficiency and environmental protection. Direct purchase from the manufacturer not only reduces cost but also provides professional technical support and after-sales service.